Inventor says recent advances in artificial intelligence enable unique paper thin shape sensors, soft robots, and printing shape in thin stronger metals to reduce vehicle weight and climate change.

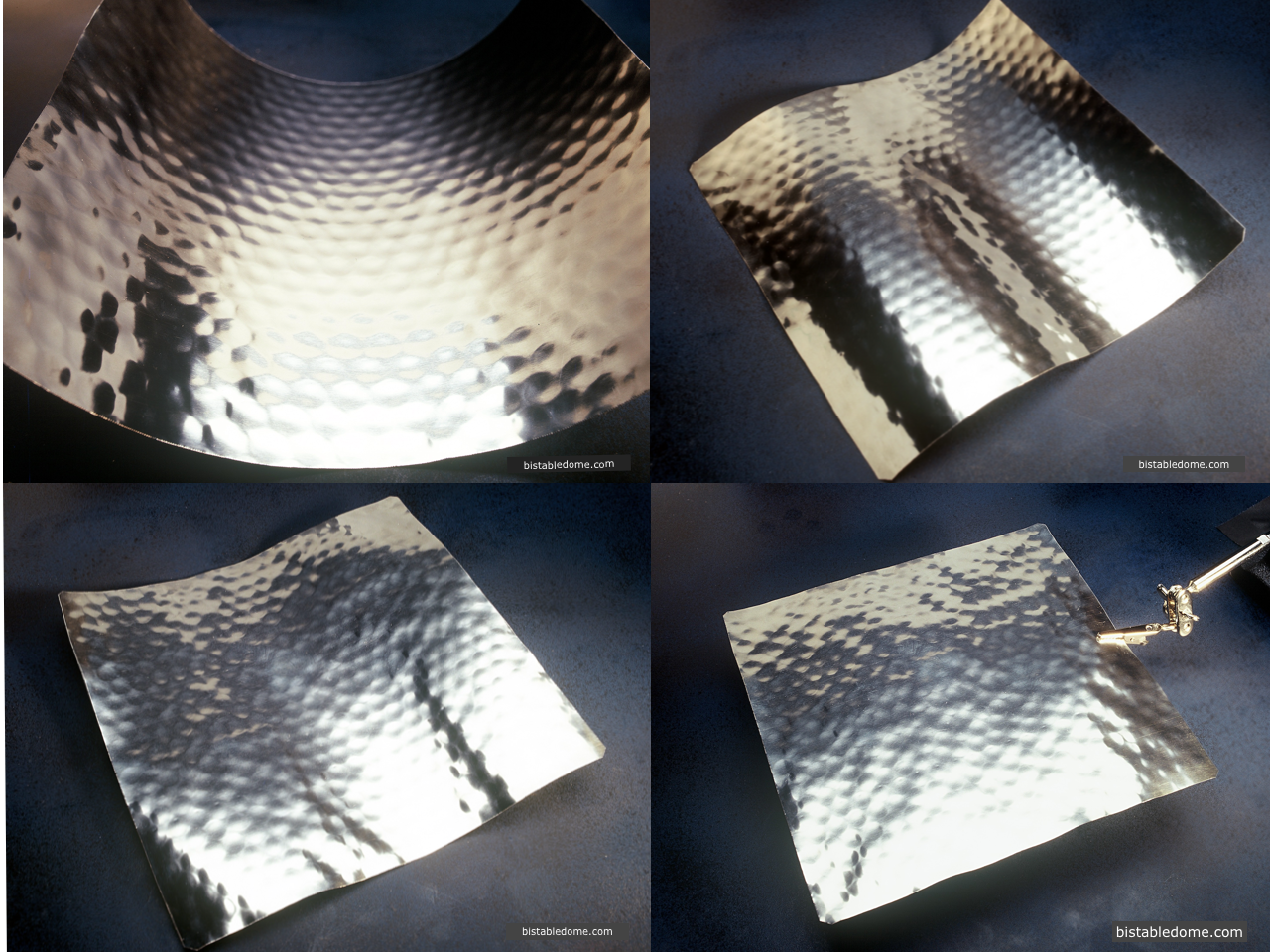

New York City, New York Mar 7, 2024 (Issuewire.com) – The website bistabledome.com describes using very shallow flex actuated overlapping bistable domes, or OBDs, to digitize, control, and utilize flexural forces in thin hard materials. Inventor Paul Ericson believes AI can drastically speed development and commercialization of a wide range of unique OBD related products.

Ericson received two patents for using OBDs formed in thin 302 stainless steel to create a contact shape sensor and a pump that pumps when bent. The website also explains how OBDs can be used to stiffen and shape high strength sheet metal.

The short video below shows behavior of equally and unequally bistable overlapping domes. At end of video are two OBD pumps of different sizes.

Overlapping bistable domes share flexural forces that switch individual bistable domes. OBDs are very shallow and in profile are usually no thicker than 3 times the original material. Rows and 2D arrays of OBDs form structures that are stiffer than the original metal.

“As long as flexural forces are not absorbed by the OBD material the structure can’t be bent without forcing OBDs to the outside of the curvature,” says Ericson.

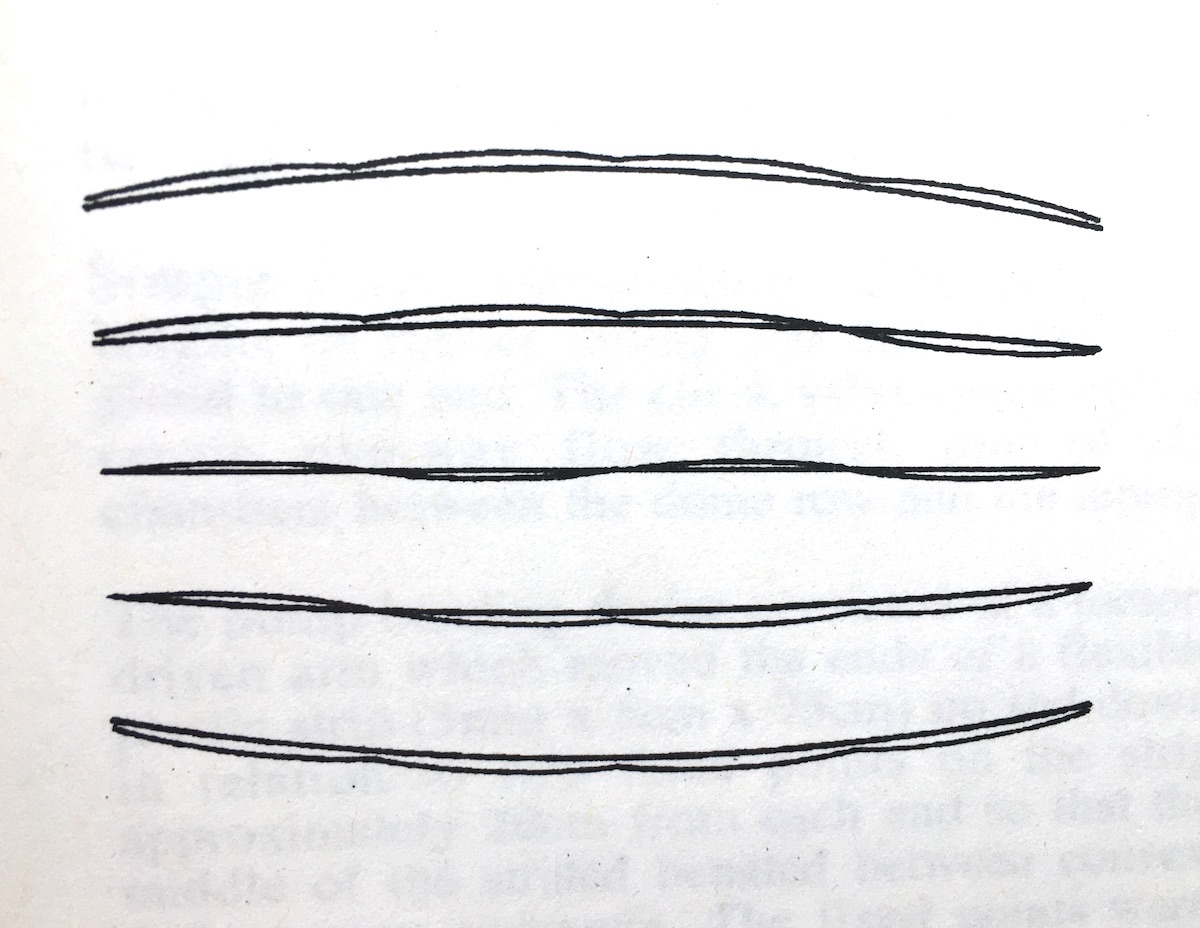

“OBD behavior is very predictable and small OBDs can be turned into on/off contact switches with paper thin flex circuitry. When kept parallel to a flexible surface a single row of OBD switches becomes a bend or 2D shape sensor capable of indicating where, how much, and in which direction from flat it is bent, regardless of its position in space. Multiple rows of OBDs can produce 3D shape information. They can be used for monitoring curvature, displacement, impact, force, motion, pressure, timing, position, weight, and fluid motion, for instance,” says Ericson.

A low resolution shape sensor prototype with 5 parallel rows of OBD switches is demonstrated at the bistabledome.com website.

Applications include softer, safer robots, smart safety bumpers, prosthetics (indentation pressure, positioning), rehab and gait analysis tools, car seat sensors for triggering airbags, smart tires, athletic and sports training tools, and more.

“About 20 years ago a few car companies considered OBDs for seat sensors but there was no AI then,” says Ericson.

AI makes OBDs more relevant and useful by enhancing pattern recognition for OBD switch behavior. Digital information from OBDs enables direct non-analog data processing, streamlining the integration of OBD shape sensing technology into applications and products. OBD sensors can help train and calibrate remote sensing and open possibilities where remote sensing is impractical or impossible.

Stiffening and shaping thin high strength steel:

Climate change is pushing the transportation industry to reduce weight. One problem is spring back, which increases the unpredictability in stamping thin high strength metals. Springback can be worse for large radius curvatures common in transportation applications.

2D arrays of equally bistable OBDs can stabilize in a wide range of shapes and radii. OBDs with a bias for one side can be used to force flat materials into desired shapes, from simple tubing to multidimensional shape. Curvature can be adjusted by adjusting OBD characteristics.

According to Ericson OBD stamping pressure is relatively low for such high strength materials because they are stamped incrementally starting at an edge and deformation is absorbed by neighboring OBDs. “It’s more like folding than stamping,” says Ericson, who claims low pressure requirements means common 3D printing materials can be used for tooling, speeding up prototyping and development.

Ericson believes an impact printer that can stamp OBDs of different characteristics, instead of letters, could produce a wide range of curvature and shape and reduce the need for expensive tooling and stamping. For large scale production OBD rollers can also be used to give shape to flat sheet materials. OBD structures are reconfigurable and can be produced and stored in a flattened form until released to take their preferred stable shape.

Coatings can be used to lock OBD orientation as well as control stiffness/flexibility and force response. “Laminates of OBD layers can be very strong for their weight and could help reduce structural framing for vehicles, boats, containers, etc.,” says Ericson.

By integrating AI-powered OBDs into vehicle design auto manufacturers can optimize shape and weight distribution to improve fuel efficiency. The shape sensing capabilities of OBDs can allow for precise adjustments to vehicle structure.

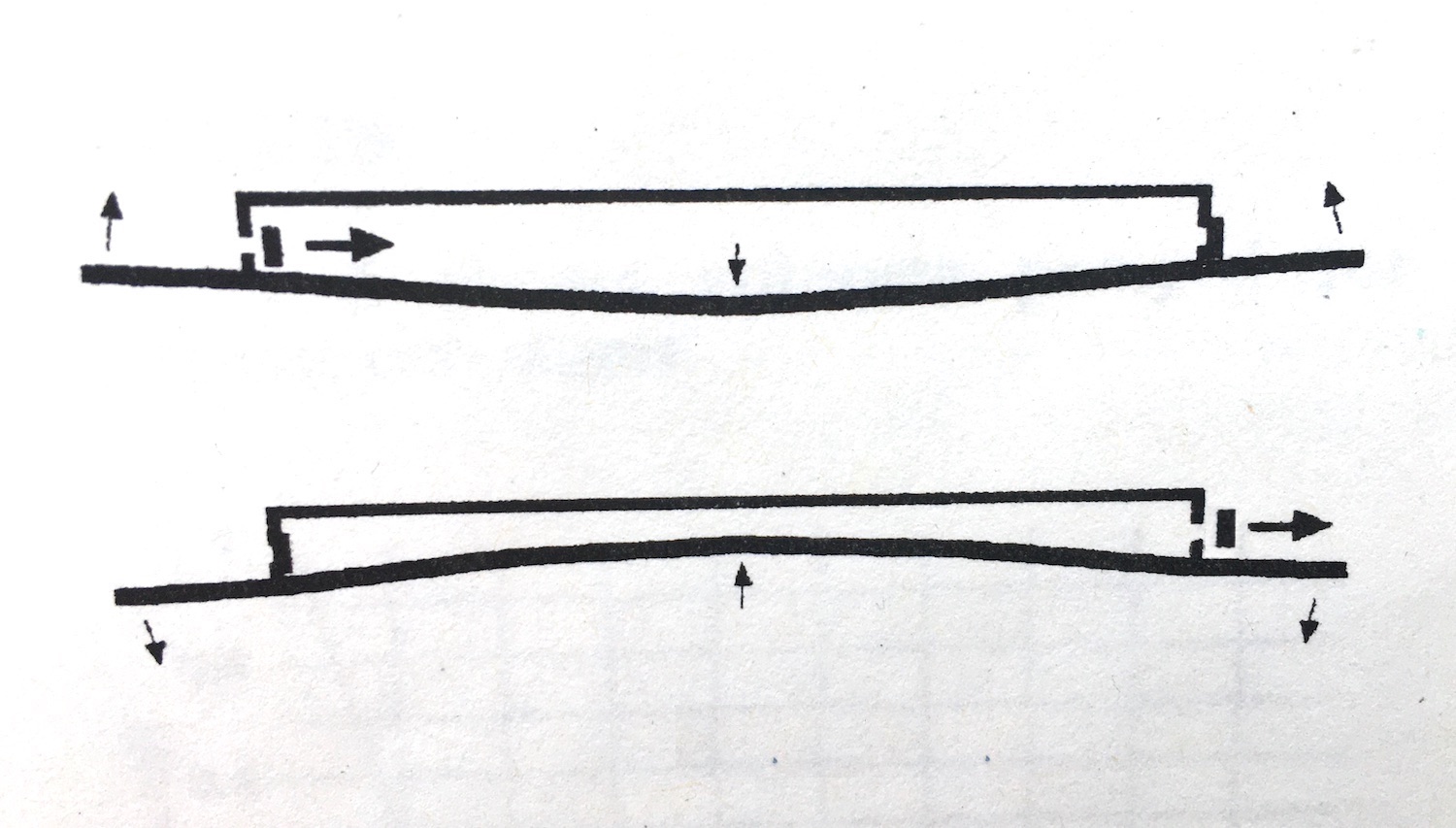

OBD pumps are very simple and made with a single OBD or a row of OBDs, a flexible housing, and check valves. They can be made in a wide range of scale and utilize any natural or mechanical motion to pump fluids or substance. Large OBD pumps might be useful in utilizing wave or subsurface water motion to pump cooler water over corals, remove unwanted sediment, or pump materials for erosion control.

Artificial intelligence can play a crucial role in developing and enhancing OBD applications and OBDs can open up many new uses for AI.

Pattern recognition: AI algorithms can be trained to recognize and correlate patterns of OBDs with specific shapes, radii, orientations, and other parameters.

Predictive modeling: AI can analyze OBD behavior and predict their response based on various factors. This can aid in designing more efficient and predictable OBD structures.

Optimization and simulation: AI algorithms can be used to optimize the arrangement and distribution of OBDs in arrays for specific applications. By simulating different configurations, AI can help identify the most effective layouts for printing shapes or strengthening thin hard metals.

Material research: AI can assist in exploring new materials or combinations to improve the performance of OBDs. By analyzing available data and conducting virtual experiments, AI can help identify materials with desired properties, such as flexibility, durability, and bistability.

Rapid prototyping: AI can facilitate the rapid design and prototyping of OBD-based structures. By generating and evaluating multiple design options, AI can help accelerate the development process and reduce the need for physical iterations.

Overall, AI can contribute significantly to the development of OBD technology by providing insights, automating processes, and enabling more efficient experimentation and optimization.

“The flex actuated bistable dome is a very simple structure but in overlapping interconnected rows and arrays it gets complicated. AI is the perfect partner for developing a wide range of unique OBD products and applications,” says Ericson.

For more information visit bistabledome.com.

Source :Bistabledome.com

This article was originally published by IssueWire. Read the original article here.

COMTEX_448897173/2777/2024-03-07T10:35:16

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Top 10 Digest journalist was involved in the writing and production of this article.